High-temperature fiberglass-reinforced phenolic honeycomb core meets all AMS 3715 requirements with optimized moisture resistance.

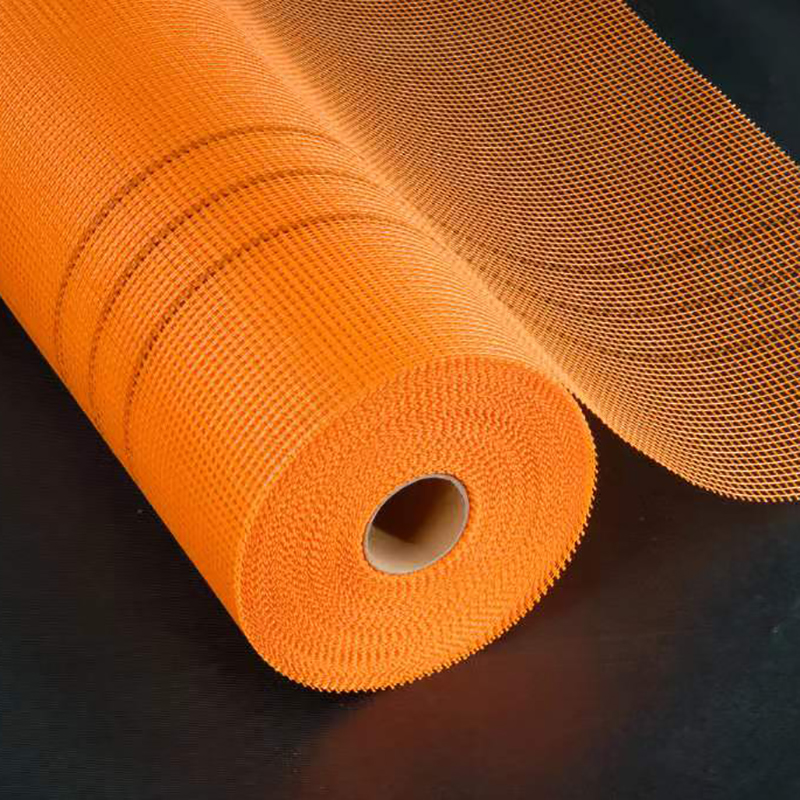

Photo Credit: The Gill Corp. Fiberglass Mesh For Stone

The Gill Corp. (TGC, El Monte, Calif., U.S.) announces the new Gillcore HF fiberglass honeycomb core, which, developed in response to industry demand from aerospace customers, meets all AMS 3715 requirements. The core is produced with a substrate consisting of woven fiberglass cloth reinforced with heat-resistant phenolic resin for improved moisture resistance over traditional aramid fiber substrates. TGC says it is suitable for high-temperature applications requiring a high degree of forming and high moisture areas.

TGC processes rolls of fiberglass cloth through the same manufacturing equipment as aramid honeycomb cores. In addition to completing its own AMS 3715 test requirements, the company is working with other customers to meet their own qualifications.

The old art behind this industry’s first fiber reinforcement is explained,with insights into new fiber science and future developments.

Market trends and tighter budgets are helping to expand the use of composites to repair and replace corrosion-damaged infrastructure — aboveground and underground.

What glass fiber users need to know about sizings, and how new sizing developments are enhancing the performance of glass-reinforced composites.

Vinyl Laminated Fiberglass Screen © 2023 Gardner Business Media, Inc. Privacy Policy [Log On]