Optimisation of cells through porous metallic components.

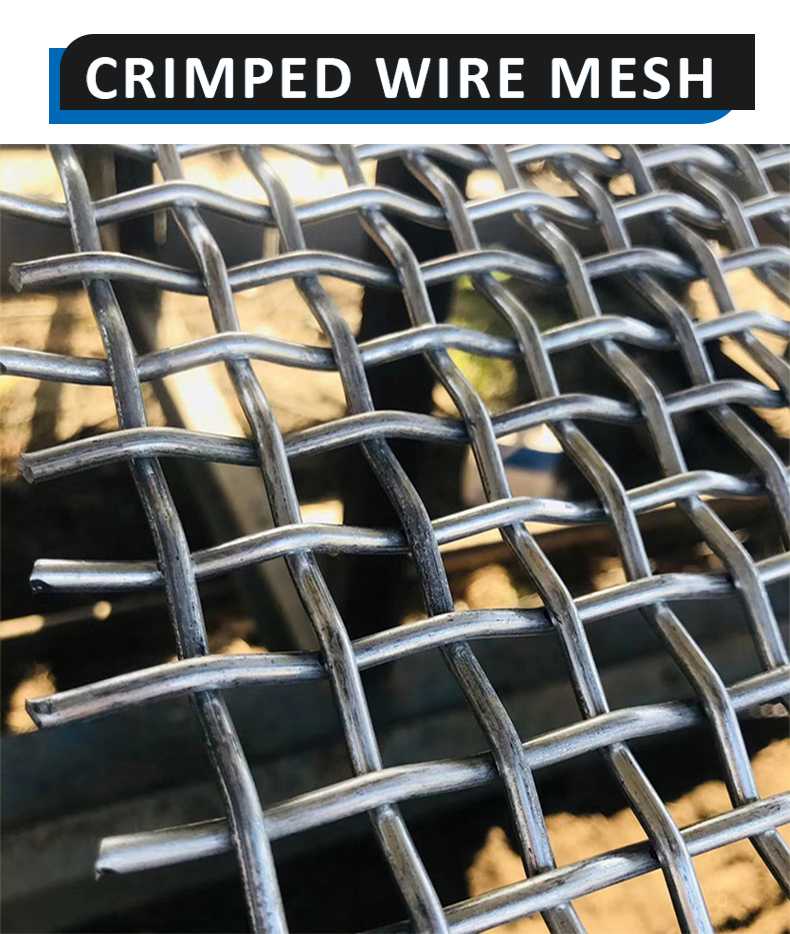

The steadily growing global hydrogen industry has unique, future-oriented prospects in the fields of energy supply, transport and logistics. To take up and use these trends economically on a large scale, materials must be flexible in their properties and automated to a high degree with regard to their manufacturing processes. This already applies to woven wire cloth, metal fibre fleece and laminates. Stainless Steel Woven Wire Screen

Some manufacturers of corresponding materials from the screening and filtration sector, which have developed into highly technical products over time, are already successful in the future market of hydrogen. Among them is the long-established German company Dorstener Drahtwerke, which offers several solutions for efficient hydrogen production, e.g. with regard to precisely scalable water, gas or ion transport. The products have special capabilities that are optimally suited for various aspects of electrolysis.

For example, suitably designed wire mesh ensures a particularly high permeability of the gas diffusion layer, while at the same time distributing the electrolyte very well. This prevents the membrane from drying out and thus protects against an undersupply of water, reduced conductivity and ultimately an undesired increase in cell voltage. Fabric thicknesses with tolerances in the μm range and a precisely definable structure also enable the design of uniform current distribution with precisely definable conductor cross-sections. In addition, they are available in many different materials, such as nickel, titanium, stainless steel and nickel-based materials, some of which are mechanically highly resilient and flexible, which can be a decisive advantage depending on the process.

Metal fibre fleeces, which are also in the portfolio of Dorstener Drahtwerke in the material titanium grade 1, among others, score points with porosities, fibre thicknesses and overall thicknesses that can be defined exactly according to customer requirements, whereby good flow rates go hand in hand with a smooth surface here. This ensures a low risk of membrane damage even at higher pressures.

A comprehensive solution that Dorstener Drahtwerke, as one of few companies in Germany, can also offer for hydrogen production based on decades of expertise, are sintered, porous laminates. These multilayer composite systems made of woven wire cloth, fibre fleeces and, if necessary, other metallic components combine all the advantages of the porous media used in each case and are as easy to handle in the production of a stack for hydrogen electrolysis as a comparable piece of sheet metal. The porous media can be adapted to each customer’s needs through optimised combination and thus ensure the greatest possible efficiency in the generation of hydrogen.

The Dorstener Drahtwerke Group has set itself the task of promoting the use of hydrogen as an environmentally friendly, cost-effective alternative to fossil fuels in the best possible way by developing and optimising its own broad product range. In this endeavour, the experience gained from more than 100 years of working with metallic materials together with the most modern production and finishing processes are incorporated into innovative products that are known worldwide for the highest quality and customer benefits.

To receive our free weekly NewsBrief please enter your email address below:

Dutch Wire Mesh © Setform Limited 2019-2023 | Privacy policy | Archive