You are browsing product catalog for

As part of the collaboration between Honeywell and ZoneFlow Reactor Technologies, LLC, the outcomes of the successful pilot plant testing represent significant improvements in efficiency and costs for new and existing steam methane reforming plants. Hydrogen Steam Generator

With the energy transition journey taking place throughout industries around the world, hydrogen is expected to play a significant role in advancing ongoing efforts.

Hydrogen is a versatile element that can be used for energy storage, as a power source, as an industrial feedstock and within other high-purity applications. When combined with production processes that have little to no carbon emissions as a by-product, hydrogen, often referred to as clean hydrogen, is perceived as a global energy solution that can help the world accelerate decarbonization efforts, especially in challenging areas such as the hard-to-abate sectors.

However, despite the extensive role clean hydrogen can play, challenges such as the need to scale up its production for commercialization all while lowering costs pose a major hurdle for its wide-scale adoption.

This is where the recent conclusion of the successful pilot plant testing conducted as part of Honeywell and ZoneFlow Reactor Technologies, LLC (ZFRT) joint agreement to commercialize the ZoneFlow™ Reactor Technology marks a significant step forward in making hydrogen production more efficient and less expensive.

Honeywell UOP and ZoneFlow Reactor Technologies, LLC had announced their collaboration in 2021 that would involve their joint efforts in growing and commercializing the ZoneFlow™ Reactor Technology.

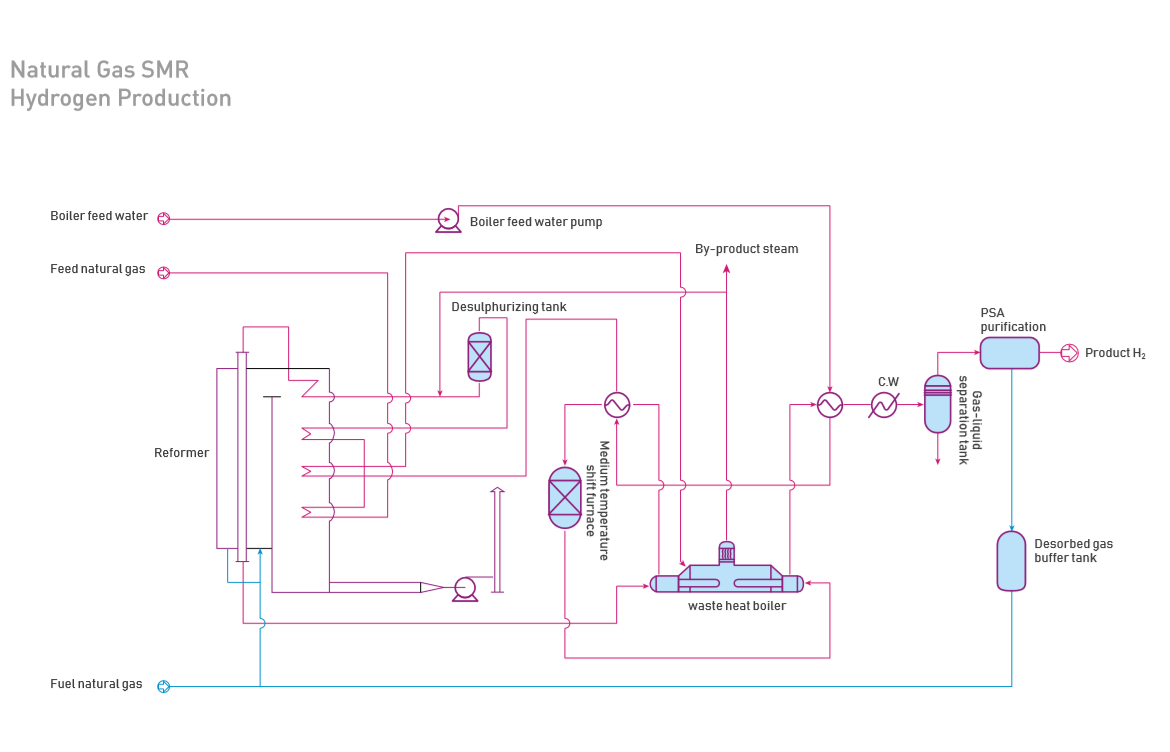

This technology can provide an improvement in the efficiency and carbon intensity of steam methane reforming (SMR), one of the most commonly used hydrogen production processes. When combined with our Honeywell H2 Solutions involving carbon capture, it enables more efficient and less expensive production of low-carbon hydrogen.

To validate the expected 15% increase in throughput over conventional catalyst pellet systems, Honeywell UOP and ZoneFlow Reactor Technologies, LLC began conducting pilot plant testing of the ZoneFlow™ Reactor in ZFRT’s large-scale pilot plant at Université Catholique de Louvain in Louvain-la-Neuve, Belgium.

Results of the Pilot Plant Testing

Two years later, the near-commercial-level testing has validated increased steam reforming capacity by at least 15%1 in terms of feed flow compared to conventional state-of-the-art pellets, with no higher methane slip and without increasing the maximum tube skin temperature or pressure drop. The increase of hydrogen production allows for the SMR to convert hydrocarbon feeds such as natural gas or naphtha and steam into synthesis gas.

“The pilot plant tests successfully concluded a decade of development and engineering work by my ZoneFlow colleagues. We look forward to rapid commercial introduction of the ZoneFlow Reactors with Honeywell, whose support has been essential in bringing us to this point,” said Bruce Boisture, President of ZoneFlow Reactor Technologies. “In the meantime, our work on other groundbreaking SMR technologies continues apace, with more announcements to follow later in the year.”

With over 800 steam methane reforming units worldwide and a similar amount used for ammonia and methanol production, the success of the pilot testing represents capital savings for new steam methane reforming plants and higher productivity for existing plants.

Influence on Energy Transition Efforts

The combination of our H2 solutions and domain expertise with ZoneFlow’s Reactor technology is helping enable high-value creation for both new and existing steam methane reforming units.

Given that ZoneFlow reactors can increase hydrogen production with existing assets, this ready-now technology can play a major role in the energy transition as refineries look to burn hydrogen instead of natural gas to lower their carbon emissions.

As the urgency for global decarbonization intensifies, the successful pilot testing represents is not only a remarkable advancement towards the scaling up and commercialization of low-carbon hydrogen production, but also signifies a major influence on the energy transition journey.

Learn more about other ways our Honeywell H2 Solutions are helping accelerate the hydrogen economy.

1Pilot Plant Test Program - Final Report, Feb 2023 delivering the results and conclusions based on detailed simulation and reconciliation of the collected data from all the test campaigns as published in PTQ Refining Gas Processing Petrochemicals publication, p. 55-61, dated Q3 (Jul, Aug, Sep) 2023. Actual performance will vary from Pilot Plant Test Program depending on many factors and constraints or usage outside of the operating conditions provided by Honeywell UOP.

Hydrogen Gas Generation Plant Sign up to receive exclusive communications about offerings, events, news, surveys, special offers and related topics via telephone, email and other forms of electronic communication.